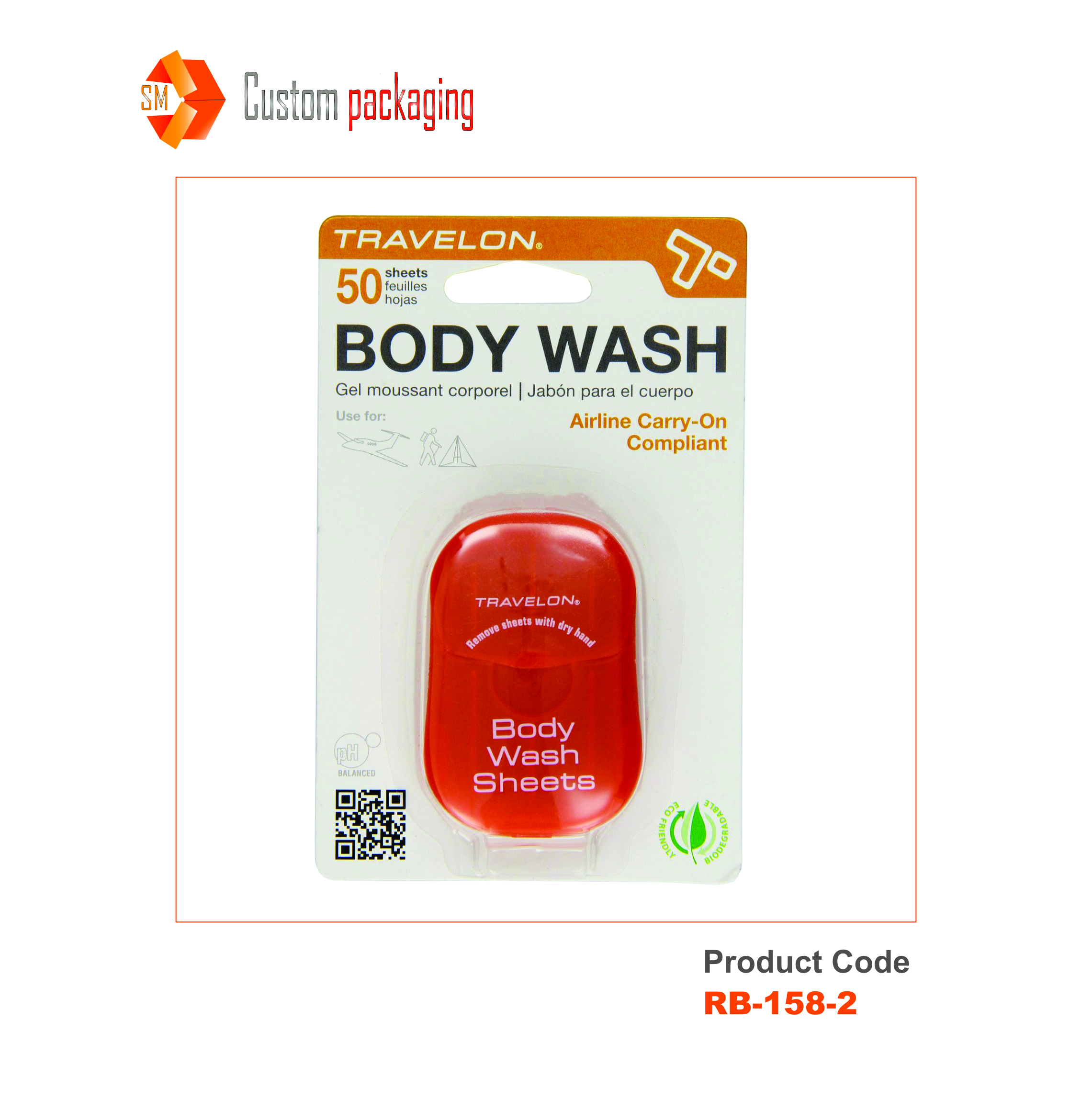

Description

Cardboard is known to be used in the construction of boxes and barrels for practical purposes.

In general, small boxes are manufactured with paper, and larger boxes are manufactured with corrugated cardboard.

Barrels may be made of pressed cardboard or metal by winding kraft paper layers until the required hardiness is obtained. Usually, the top is made of the same material as the base. The disparity between carton and paperboard, which is the press’s uniform density, also gives the product greater luminosity and consistency.

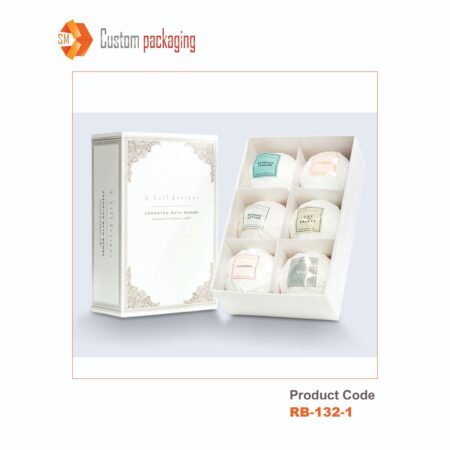

When a box is printed, a paperboard must ensure good quality and visual consistency of the product.

The box is intended to produce a package that meets the customer’s business requirements and the product’s requirements in the box that specifies the style, cardboard shape, corners, shutdowns, joint types, and other package factors.

It is necessary to note that when you indicate the box’s size, the order must be the front, bottom, and height at all times (i.e., length, width, and depth).

In addition to several coatings that can increase those characteristics, such as water resistance, fattening resistance, visuality, etc., several different cardboards can be used to make small folding boxes.

However, the selected carton must meet the basic needs set out, such as correct ink sticking, good print surface for quality printing, accurate acceptance of stickers, and easy installation without causing cracks, wrinkles, or tears during folding.

Reviews

There are no reviews yet.